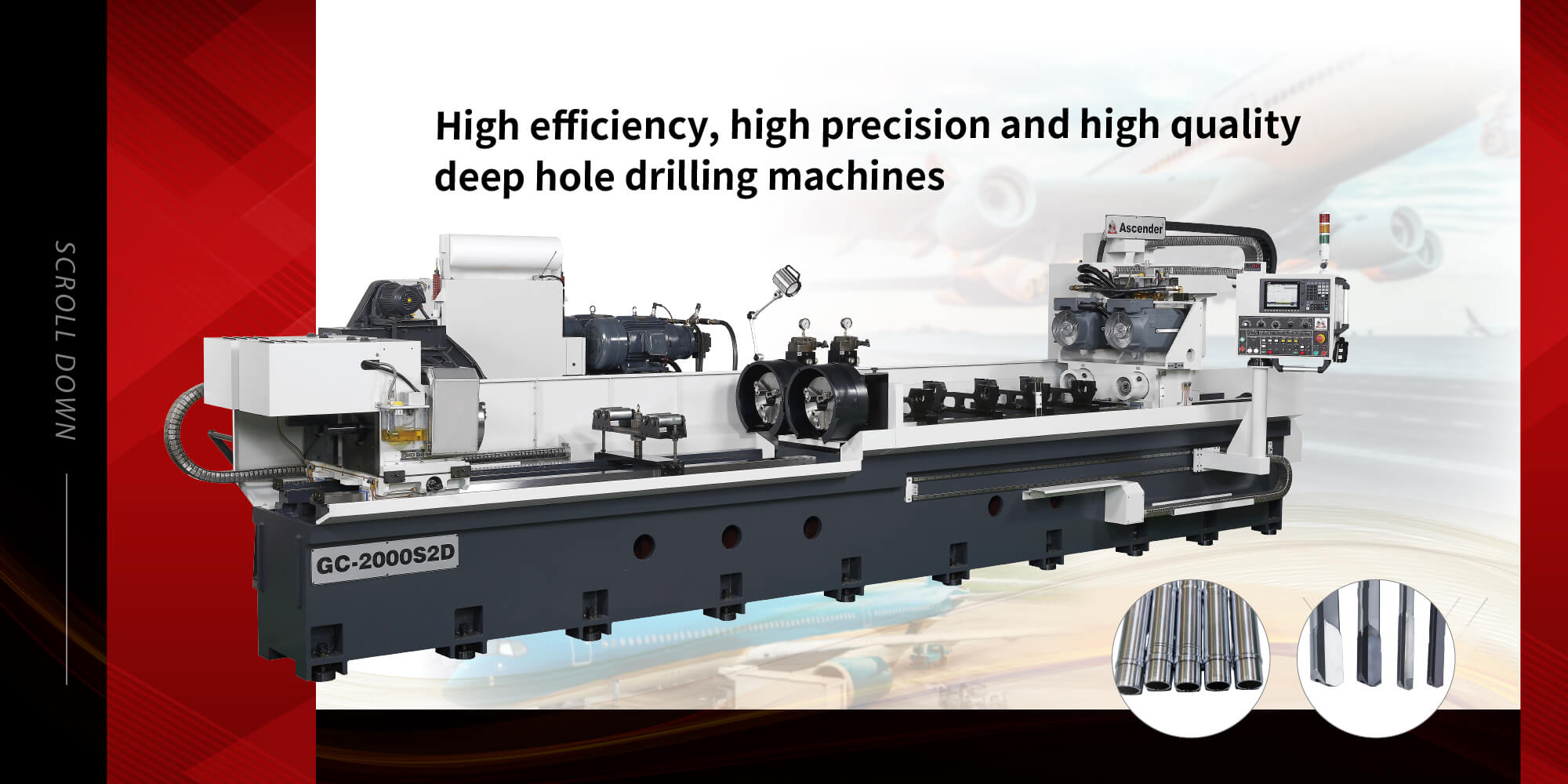

MIT PROCESSING , Made in Taiwan

- 店家商品

- TG GunDrill Series GC GunDrill Series BTA System Series Trepanning Machines Tool Accessories Peripheral Products Chip Compactor

ASCENDER MACHINERY-Deep Hole Drilling Machine

店家文章分享

Selection of Gun Drilling and BTA Drilling

Gun Drilling vs. BTA Drilling: Choosing the Right Technology

The Evolution of Deep Hole Drilling Technology

Origin and Development of Gun Drilling

Gun drilling technology dates back to the 17th century when gunsmiths needed to drill long, straight, high-precision bores for firearm barrels, ensuring shooting accuracy. This led to the development of specialized gun drilling techniques.

High straightness and precision, using internal coolant to reduce bore deviation.

Suitable for small-diameter deep hole machining, ranging from 2mm to 30mm.

High-pressure coolant improves machining efficiency.

Development and Application of BTA Drilling

As industrial demands grew, gun drilling efficiency became limited for large-diameter and deep-ratio bores. By the mid-20th century, BTA drilling technology emerged to meet the needs of defense, energy equipment, and heavy machinery manufacturing.

Ideal for large-diameter and high-performance deep hole machining (diameters above 30mm).

Internal chip removal design ensures a more stable machining process.

Used in hydraulic cylinders, aerospace components, defense equipment, and energy industries.

Comparison Between Gun Drilling and BTA Drilling

| Technology | Hole Diameter Range | Main Applications | Advantages |

|---|---|---|---|

| Gun Drilling | 2mm – 30mm | Precision machining, mold cooling channels, medical instruments, automotive components | High precision, excellent straightness |

| BTA Drilling | 30mm and above | Heavy machinery, aerospace components, defense equipment, energy pipelines | High efficiency, large hole diameters, internal chip removal |

#deep hole machining #gun drilling #gundrill #GunDrill #BTA drilling #precision machining #CNC deep hole machining #BTA #deephole #drill

其它相關店家資訊