MIT PROCESSING , Made in Taiwan

窩客幫 │

工程網 │

家事網 │

加工網 │

MIT製造網 │

MIT新聞網 │

清潔服務 │

搬家網 │

租車網 │

維修網 │

學習網 │

愛美網 │

開鎖網 │

好家網 │

掏客網 │

小華陀 │

野外生活網 │

目前瀏覽人數891

- 店家商品

- TG GunDrill Series GC GunDrill Series BTA System Series Trepanning Machines Tool Accessories Peripheral Products Chip Compactor

推薦店家

玉宗股份有限公司

EOS 愛歐斯車美工藝

捷美汽車(包膜)美容工藝坊-汽車包膜,車體包膜,台中汽車包膜,大甲汽車包膜

承昌油漆工程

Amy手機現場維修-手機維修,台南手機維修

怪獸三十八商行-手機殼,手機殼專賣,台北手機殼,士林區手機殼,

家樂美健康事業有限公司

全人健康股份有限公司

盛鑫实业股份有限公司|高速制罐机械

Cynosura international co.,ltd-Car lamp manufacturing, car l

匠德精密焊接-台中焊接加工/五金焊接

達特車業-汽車改裝,汽車維修,台中汽車維修,台中汽車維修廠,大雅區汽車維修,大雅區汽車維修廠

Mit推薦

客戶新選

友站連結

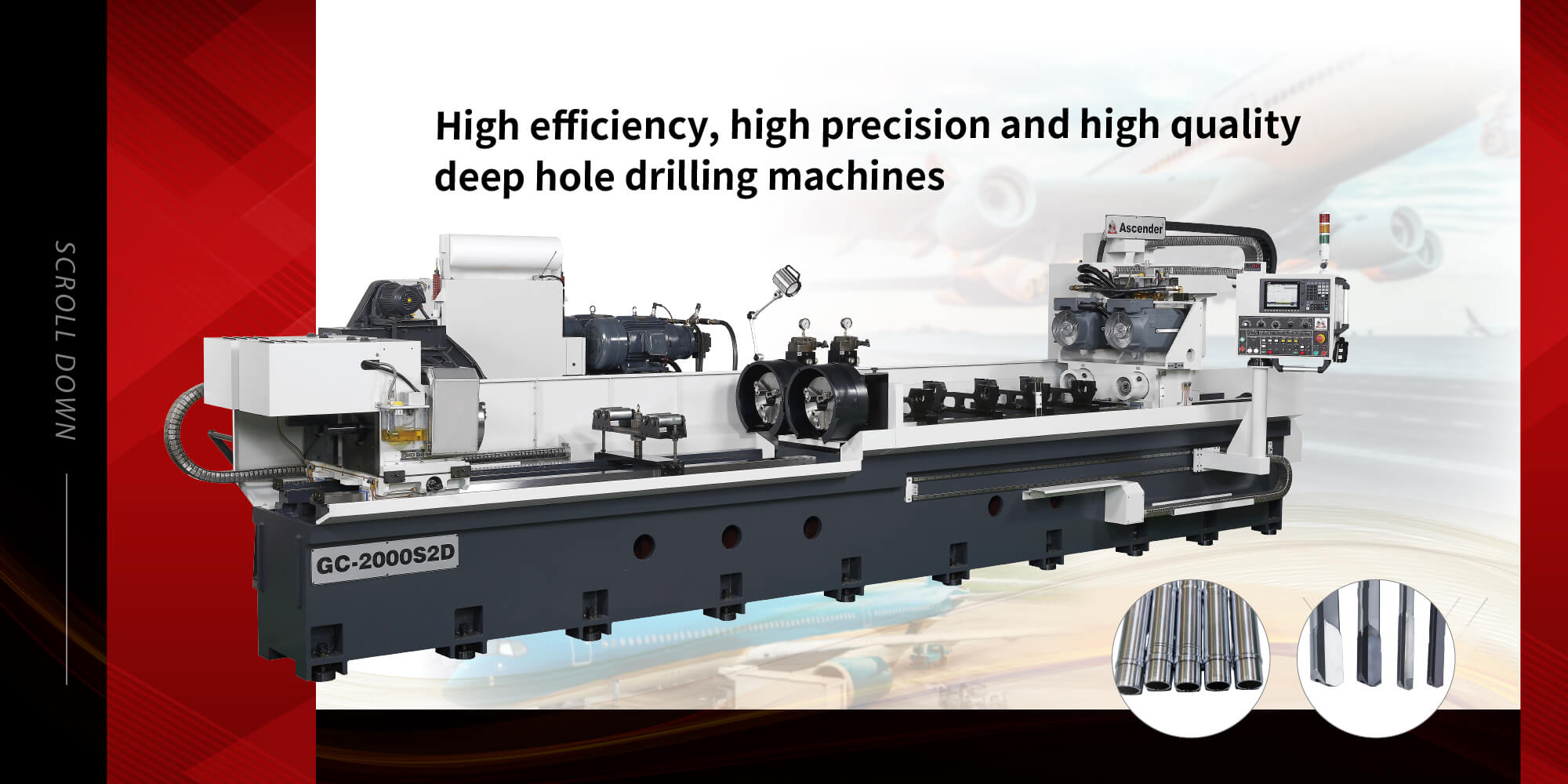

ASCENDER MACHINERY-Deep Hole Drilling Machine

店家文章分享

What is deep hole drilling?

2025-03-27

Deep Hole Drilling Guide

Mastering Deep Hole Drilling Techniques to Enhance Precision and Efficiency

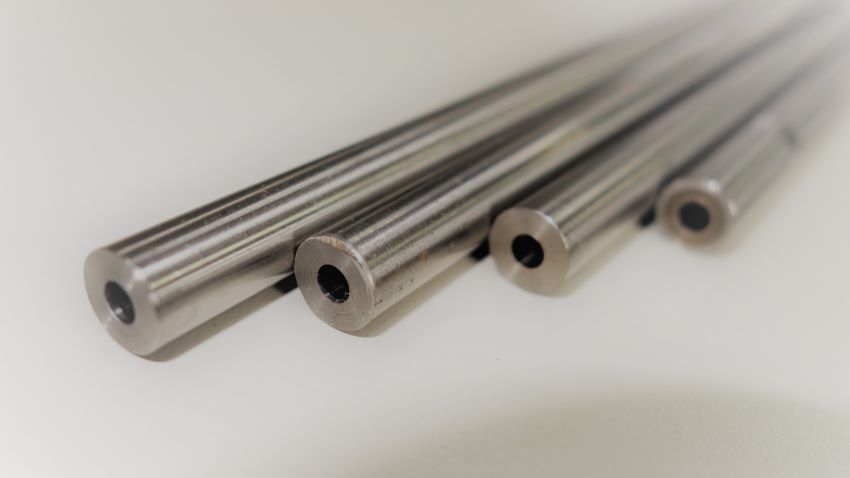

In machining, when the hole depth exceeds 10 times the hole diameter (Deep Hole = Depth / Diameter > 10), specialized deep hole drilling techniques are required to ensure precision and stability.

Key Techniques for High-Quality Deep Hole Drilling

Choosing the Right Drilling Method

- Gun Drilling – Ideal for small-diameter, high-precision applications.

- BTA Drilling – Suitable for large-diameter and high-efficiency drilling.

Optimizing Cutting Conditions

- Set appropriate spindle speed and feed rate to prevent overheating.

- Use high-pressure coolant to improve chip evacuation.

How to Prevent Scratches When Retracting

Controlling Retraction Speed

- Use slow and uniform retraction to reduce tool-wall contact pressure.

- Implement segmented retraction to ensure chip evacuation.

Enhancing Cooling and Lubrication

- Use high-pressure coolant to flush away chips.

- Select low-viscosity cutting oil suitable for the material.

Maintaining Machine and Process Stability

- Ensure machine rigidity to minimize vibrations.

- Keep the hole clean by using air or coolant flushing.

Precision Control for Higher Quality

By optimizing retraction speed, improving cooling, and ensuring machine stability, deep hole drilling can significantly reduce surface scratches and enhance hole quality.

#deep hole machining #gun drilling #gundrill #GunDrill #BTA drilling #precision machining #CNC deep hole machining #BTA #deephole #drill

其它店家文章

2025-03-27

2025-02-14

2024-11-13

2024-04-17

2023-11-17

2023-08-07

2023-08-07

服務項目:

金屬加工機械,工具機,機械/其它,機械部件/其它

特別關鍵字:

Deep Hole Drilling Machine,Deep Hole Drilling Machine Manufacturer,Deep Hole Drilling Machine Factory,Taichung Deep Hole Drilling Machine,Taichung Deep Hole Drilling Machine Manufacturer,Taichung Deep Hole Drilling Machine Factory,Gun drilling,Taichung Gun drill Machine,Taichung Gun drilling,Shengang Gun drill Machine,Shengang Gun drilling,Gun drilling,Taichung Gun drilling,Shengang Gun drilling,Shengang Deep Hole Drilling Machine

其它相關店家資訊